During the construction of the animal feed mill plant, the first consideration for customers is how to reduce the initial investment, build and put into production as soon as possible, so as to obtain production benefits. The specific investment includes land costs, equipment costs and later maintenance costs. For the contractor, how to help customers achieve “cost reduction and efficiency increase” in the construction of animal feed mill plants is the key pursuit and other goals.

Measures to reduce costs and increase efficiency in the construction of animal feed plants

To achieve the goal of reducing costs and increasing efficiency of animal feed mill plant, the following aspects should be specifically considered:

(1) Determine the feed variety and production scale

Due to the large number of animal feed manufacturing plants in my country, investors should analyze regional characteristics and market goals in advance before building factories, avoid blind investment, select feed varieties reasonably and scientifically, and determine the production scale according to local breeding conditions.

(2) Determine the production workshop structure

The construction period of concrete structure is long, the cost is low, and the working environment of the animal feed mill plant workshop is good; the construction period of steel structure workshop is short, the cost is high, and the working environment of the workshop is poor, but it can be recycled. Feed production has high environmental requirements, so concrete is the workshop structure chosen by more animal feed mill plants.

(3) Select the production process and equipment

The production process directly affects the purchase of equipment and product quality by feed manufacturers. Choosing a partner with better technical strength and experience can help you achieve twice the result with half the effort. “Powder first and then mix” is a production process that animal feed processing plants choose more, which can not only save storage space, but also reduce processing costs to a certain extent.

According to the animal feed production line design and configuration of reasonable production equipment, the selection of production equipment is the dominant factor related to the quality and cost of finished products. According to the requirements of animal feed mill plant output, environmental protection, quality, etc., the types of supporting equipment selected for each section are also different.

(4) Pay attention to the equipment of auxiliary equipment

While focusing on the main animal feed mill plant equipment, we should also pay attention to the selection and installation of auxiliary equipment. For example, taking the crushing equipment as an example, the crushing air network lacks the necessary settlement space, which is easy to cause the blockage of the pulse dust collector, which will directly affect the performance of the main engine. play.

(5) Plant construction is centered on workshop construction

Try to ensure the distance between the workshop and the raw material warehouse and finished product warehouse, so that they are connected together. The boiler room, power distribution room, machine repair room, etc. should also be distributed around the main workshop, so as to reduce the time of personnel walking and save the cost of circuit loss.

(6) Reasonable arrangement of equipment maintenance

Standardized operation and good maintenance can ensure the normal operation of production equipment and increase the service life. Turning post-repair into pre-maintenance is conducive to reducing production costs and improving production efficiency.

How to reduce material loss in animal feed mill plants

With the rapid development of the feed industry, material loss has attracted great attention from animal feed production lines. Generally, the loss of raw material input and output should be controlled below 0.6%, but there are still animal feed plants reaching 0.7-0.8%. We should reduce the loss from the following aspects.

(1) Raw material moisture

Purchasing raw materials should check the moisture according to the specified standards. The higher the moisture content of the raw materials, the greater the loss, especially for corn. In the procurement process, the moisture control standards should be refined to reduce the negative impact of the loss of high-moisture raw materials.

(2) Raw material temperature

Protein raw materials such as soybean meal and peanut meal are not completely cooled due to the eagerness of suppliers to supply them. During transportation, they will continue to cool and lose water. This is also a loss of raw materials. Therefore, some raw materials must be completely cooled before weighing. (Related post: Feed mill plant in Uzbekistan)

(3) Raw material storage

If conditions permit, use tons of bags instead of bags. Conditional feed mills will use silos with better airtightness for large quantities of raw materials to prevent harmful rodents and insects from entering, and effectively reduce mildew and other losses during storage.

(4) Use of raw materials

In the feeding section of animal feed mill plant, use the raw materials according to the first-in first-out system to avoid the storage time of the previous materials being too long; in the crushing section, avoid excessive crushing, adjust the air volume of the crushing chamber and reduce the temperature; in the mixing section, especially in the months when the temperature is high, at this time If the moisture content of the raw material is low, the addition of water to the mixer must be considered, and the proportion of water added should be calculated according to the external temperature.

(5) Finished product packaging

Packing scales belong to quantitative packaging equipment in animal feed mill plant. If they are not standard, the loss will be large, so proofreading is required for each class. It is best to use coated bags for packaging bags to avoid powder leakage and feed moisture loss.

In today’s highly competitive market, reducing material loss is to reduce the production cost of the animal feed mill plant and improve the overall efficiency, so it is necessary to carry out refined management for each production link.

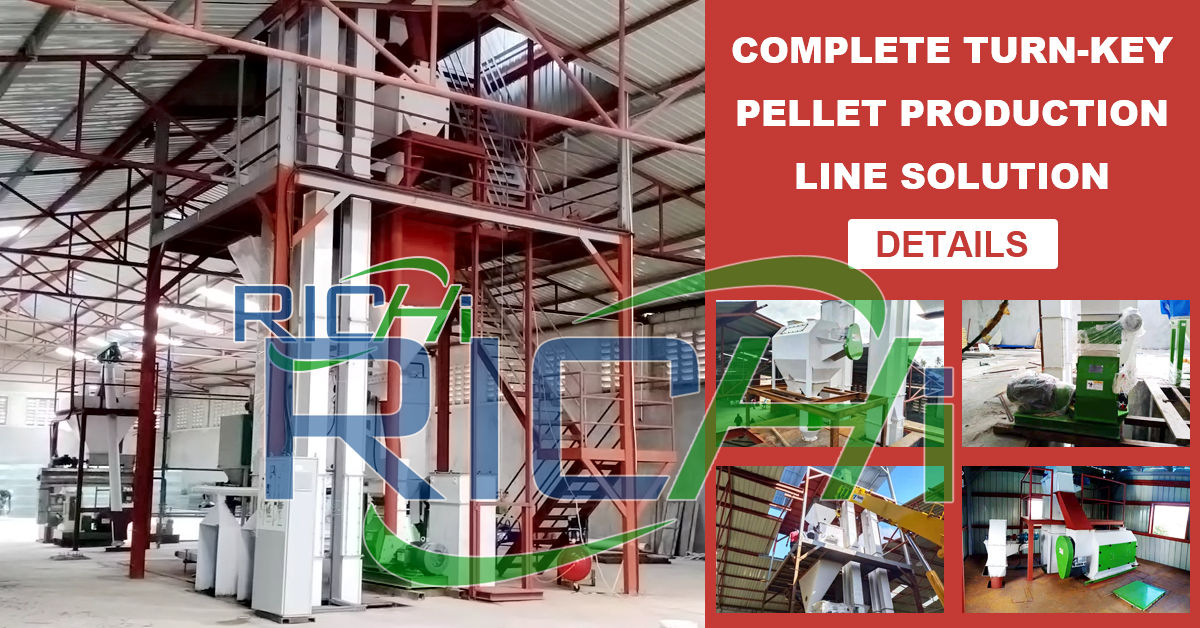

Richi Machinery specializes in the research and development, design and manufacture of animal feed mill plants, which can help feed enterprises put into production quickly and seize market opportunities. Welcome new and old customers who have invested in the production of animal feed to contact us.