In the world of alfalfa pellet production, two main types of machines dominate the market: ring die and flat die pellet making machines. While both serve the purpose of converting alfalfa into compact, easily manageable pellets, the ring die alfalfa pellet making machine typically comes with a higher price tag. This article explores the reasons behind this price difference, shedding light on the advantages and capabilities that justify the higher cost of ring die machines.

- Production Capacity and Efficiency

One of the primary reasons for the higher price of ring die alfalfa pellet making machines is their superior production capacity and efficiency:

- Higher Output: Ring die machines can produce significantly larger quantities of pellets per hour compared to flat die machines. This increased capacity is crucial for large-scale operations and industrial use.

- Continuous Operation: Ring die machines are designed for continuous, 24/7 operation, making them more suitable for high-volume production environments.

- Energy Efficiency: Despite their higher output, ring die machines often demonstrate better energy efficiency per ton of pellets produced, leading to long-term cost savings.

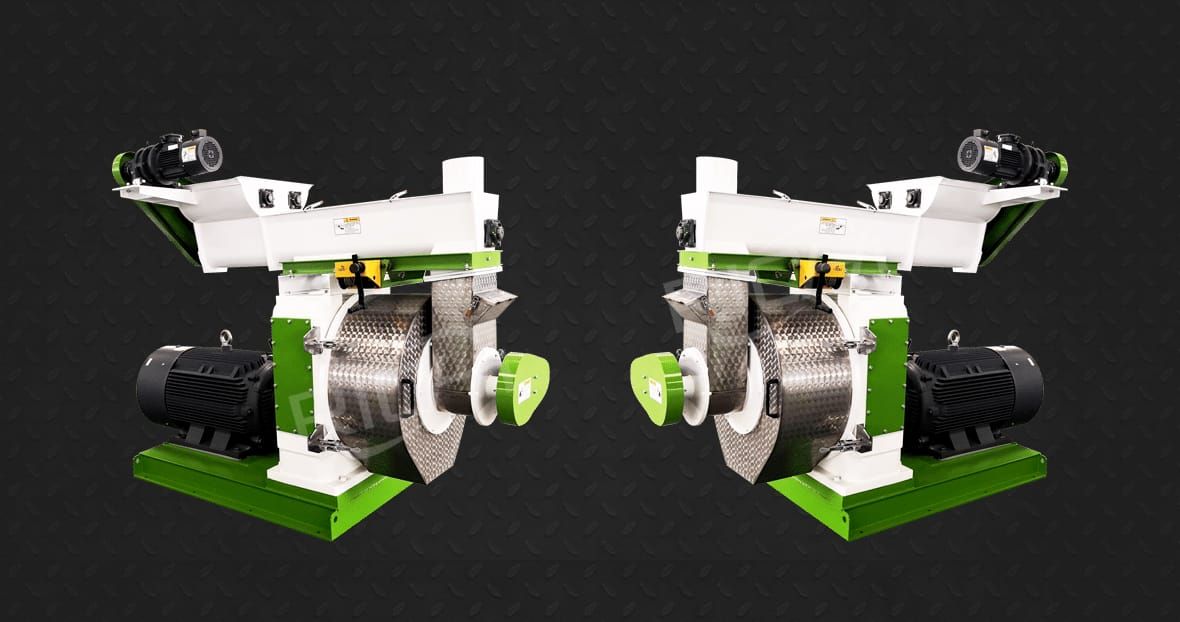

- Advanced Technology and Design

The ring die pellet making machine incorporates more advanced technology and design features:

- Complex Mechanical Structure: The rotating die and roller system in ring die machines is more complex than the stationary die in flat die machines, requiring more sophisticated engineering.

- Precision Manufacturing: The components of ring die machines, especially the die itself, require higher precision in manufacturing, contributing to the overall cost.

- Advanced Control Systems: Many ring die machines come equipped with more advanced control systems for monitoring and adjusting the pelleting process in real-time.

- Durability and Longevity

Ring die alfalfa pellet making machines are built to withstand the rigors of high-volume, continuous production:

- Robust Construction: These machines are typically constructed with higher-grade materials to handle the stress of continuous operation.

- Wear Resistance: The components, especially the die and rollers, are designed for enhanced wear resistance, leading to longer operational life.

- Lower Maintenance Frequency: While maintenance costs might be higher, the frequency of required maintenance is often lower due to the machine’s robust design. (Related post:Grass Pellet Machine)

- Versatility in Raw Material Processing

Ring die machines offer greater versatility in handling different types of raw materials:

- Adaptability: They can more easily process a variety of biomass materials beyond alfalfa, such as wood chips, straw, or other agricultural residues.

- Consistency in Pellet Quality: Ring die machines typically produce more consistent pellet quality across different raw materials and moisture contents.

- Pellet Quality and Characteristics

The pellets produced by ring die machines often have superior characteristics:

- Higher Density: The design of ring die machines allows for the production of denser pellets, which is desirable for both feed and fuel applications.

- Better Durability: Pellets from ring die machines tend to be more durable, reducing breakage during handling and storage.

- Uniform Size and Shape: The rotating die system contributes to more uniform pellet size and shape, which is important for consistent feeding and combustion.

- Scalability and Future-Proofing

Investing in a ring die alfalfa pellet making machine often provides better scalability for growing businesses:

- Expandability: Many ring die systems are designed with the potential for future capacity increases through upgrades or additional modules.

- Market Adaptability: The versatility of ring die machines allows businesses to adapt to changing market demands, such as switching between feed and fuel pellet production.

- Research and Development Costs

The higher price of ring die machines reflects the significant investment in research and development:

- Ongoing Innovation: Manufacturers of ring die machines often invest heavily in R&D to improve efficiency, reduce wear, and enhance pellet quality.

- Specialized Engineering: The design of ring die systems requires specialized engineering knowledge, which adds to the overall development costs.

- Manufacturing Complexity

The production process for ring die machines is more complex and costly:

- Precision Components: The rotating die and roller system requires high-precision manufacturing, which is more expensive than the simpler flat die design.

- Quality Control: More rigorous quality control measures are typically employed in the production of ring die machines, adding to the manufacturing costs.

- Market Positioning

Ring die alfalfa pellet making machines are often positioned as premium products in the market:

- Industrial-Grade Equipment: They are typically marketed towards large-scale operations and industrial users, who are willing to pay more for higher capacity and efficiency.

- Brand Reputation: Established manufacturers of ring die machines often command higher prices due to their reputation for quality and reliability.

- After-Sales Support and Service

The higher price often includes more comprehensive after-sales support:

- Technical Expertise: Suppliers of ring die machines typically offer more specialized technical support and training.

- Spare Parts Availability: Due to the more complex nature of ring die machines, a more extensive inventory of spare parts is usually maintained, adding to the overall cost.

- Regulatory Compliance

Ring die machines are often designed to meet stricter regulatory standards:

- Safety Features: They may incorporate more advanced safety features to comply with industrial safety regulations.

- Emissions Control: In some cases, ring die machines may include features to help meet environmental regulations, particularly for fuel pellet production.

- Return on Investment Considerations

While the initial cost is higher, ring die machines often offer a better long-term return on investment:

- Higher Production Volumes: The ability to produce larger quantities of pellets can lead to faster recovery of the initial investment.

- Operational Efficiency: Lower energy consumption per ton of pellets produced can result in significant cost savings over time.

- Versatility: The ability to process various raw materials and produce different types of pellets can open up new market opportunities.

Conclusion

The higher price of ring die alfalfa pellet making machines compared to flat die machines is justified by their superior capacity, efficiency, durability, and pellet quality. While the initial investment is greater, these machines offer significant advantages for large-scale operations and businesses looking for long-term growth and versatility in pellet production. The advanced technology, robust construction, and potential for better long-term returns make ring die machines a preferred choice for many industrial and large-scale agricultural operations.

For businesses considering an investment in alfalfa pellet production equipment, it’s crucial to assess their current needs, future growth plans, and overall operational goals. While flat die machines may be suitable for smaller operations or those just starting, ring die alfalfa pellet making machines offer the capacity, efficiency, and versatility needed to compete in larger markets and adapt to changing industry demands. The higher price tag of ring die machines reflects not just the equipment itself, but an investment in advanced technology, production capability, and future-proofing for growing businesses in the competitive world of biomass pellet production.