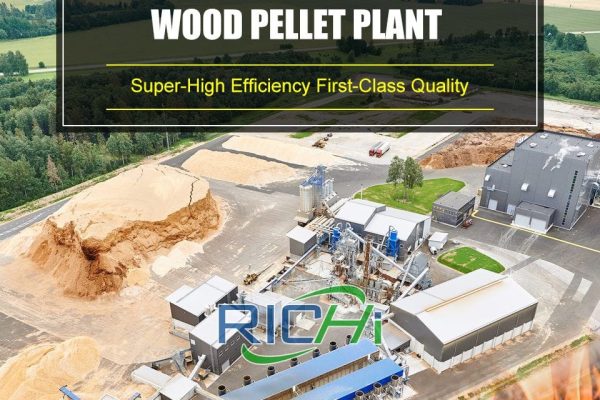

Raw Materials for a 1 T/H Wood Pellet Production Line in Spain

Spain, with its robust forestry industry and growing focus on renewable energy, presents an excellent opportunity for establishing a wood pellet production line. When considering a 1 ton per hour (T/H) capacity plant, the selection of appropriate raw materials is crucial for ensuring efficient production and high-quality pellets. This article explores the various raw materials…