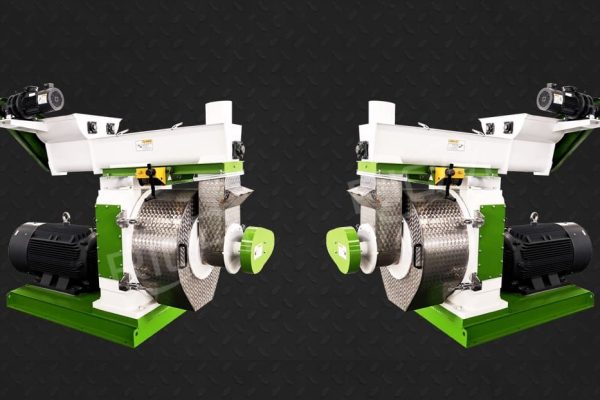

Key Differences Among Various Brands of Organic Fertilizer Pellet Machines and Why RICHI Ring Die Pellet Machine is the Optimal Choice

Organic fertilizer pellet machines play a crucial role in modern agriculture by transforming raw organic materials into uniform and easy-to-use pellets. With numerous brands available, each offering unique features and advantages, it is essential to understand the key differences among them. This article delves into the main distinctions between popular brands and explains why the…