The biomass energy industry has developed rapidly in China in recent years. It is a good choice to invest in the construction of a biomass wood pellet mill plant. As a biomass energy equipment manufacturer, Richi Machinery has been specialized in wood pellet mill for sale for many years, and will provide you with some information.

The first thing to do is to do a survey on the local market. Is there a big demand for wood pellets? How is the competition? Is the wood pellet mill plant ready? When the preparatory work is done, I don’t think I need to say more, because the investment in this industry is still relatively large, and everyone will not enter this industry in a hurry. (Related post: wood pellet mill for sale)

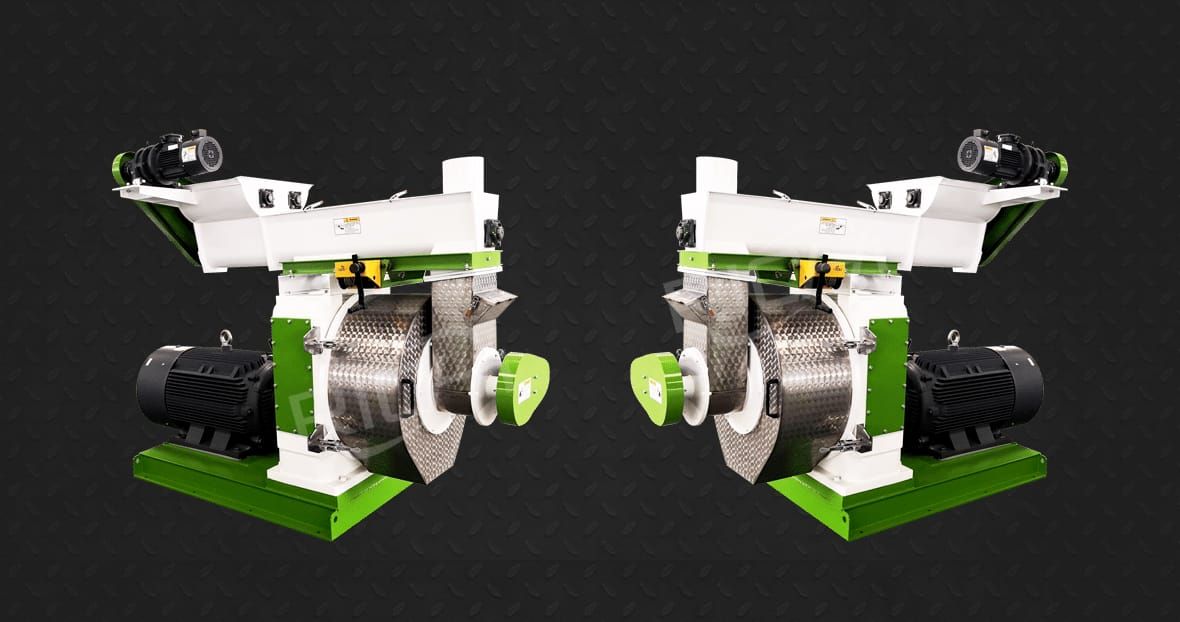

If the preparations are done, the next step is to choose a manufacturer of wood pellet mill plant equipment. There are two options here. One is to find a manufacturer to customize a complete set of wood pellet production lines, which saves time and effort and is guaranteed, but the investment is large.

(2) The other is to purchase the core, wood pulverizer, biomass wood pellet mill. Then other equipment is equipped by yourself, so that the wood pellet mill plant investment is less, but the requirements are higher, and you need to be knowledgeable about machinery. Which method is good, choose according to your actual situation.

A general biomass wood pellet mill plant includes: wood pellet granulator, pulverizer, screening equipment, cooling equipment, environmental protection dust removal equipment, packaging equipment, and drying equipment if necessary. All kinds of auxiliary equipment, fans, cyclone, belt conveyors. According to different wood pellet mill plant production capacity, the size and model of the output equipment are different, and the price is also much different, and the specific situation depends on the situation.

For the installation of the wood pellet mill plant, we all go back to people to install it. There will also be after-sales service in the later stage, please rest assured. We will give guidance. To invest in the construction of biomass wood pellet mill plant equipment manufacturers, the first thing you need is a reliable biomass wood pellet mill plant company.

Richi Machinery is a pelletizing machine manufacturer specializing in the wood pellet mills for sale, if you are interested in our biomass pellet plant and wood pellet factory projects and solutions, please leave your needs and email, WhatsApp and other contact information, our sales staff will provide professional answers and corresponding product pictures, videos and quotations.

1. Importance of cooling section in wood pellet mill plant:

The importance of the process cooling section of the wood pellet mill plant:

Regarding the production of biomass pellets, each time a whole wood pellet mill plant is matched, we need to match the corresponding equipment according to the raw materials.

Normally, for a complete wood pellet mill plant, we need the following sections; from the crushing section of raw materials to the crushing section, and the crushed materials directly enter the wood dryer, which can effectively improve the efficiency of the drying equipment.

After drying the material, within the feeding requirements of the wood granulator, the finished granules can be produced. After the pellets are produced by the wood pellet mill, they then enter the cooling section, and then pack the cooled pellets. Today we will talk about the cooling section in the entire wood pellet mill plant.

The cooling section mainly comes from the cooling of finished pellets. The cooling equipment we mainly use includes cooling bins and counter-flow coolers. For many customers, I only need to pack the pellets directly after they are produced. In this way, one working section can be reduced.

However, after the pellets come out, the surface temperature is about 60-80℃, and the pellets produce some water during the high pressure process. If the pellets containing water vapor on the surface are directly sealed and packaged, it will affect the gloss of the pellets themselves, and will cause the pellets to crack, and the powder formation rate will be high.

In this case, the sales price of the pellets will be greatly affected. In contrast, the advantage of the cooling section is that the pellets can be cooled by counter-flow cooling, and then the dust of the pellets can be collected, which can improve the forming rate of the pellets and ensure the selling price of the pellets.

Regarding the cooling section, it is very necessary to increase the entire wood pellet mill plant, so as to ensure that the pellets produced are more standard and the appearance is more beautiful. (Related post:fuel pellet plant )

2.Wood pellet mill price and quality which is more important

The wood pellet mill cost is a commonplace question. We have written a lot of articles about the price of wood pellet machines before. The price of a specific set of wood pellet mill plant or the price of a single wood pellet mill machine has an approximate amount. So today, let’s discuss which is more important, the price and the value of wood pellet mill?

The wood pellet machine price is relatively transparent in the whole industry, but according to the size and strength of the manufacturer, different manufacturers have different pricing for different models of wood pellet mill. It can be said that if you only pay attention to the price of wood pellet machine when you first come up, then you cannot buy good equipment.

As the saying goes, seeing is believing, hearing is believing, if you can’t see the specific equipment, don’t judge its price out of thin air. The price difference between Audi and Alto is not a little bit, and their quality can be imagined.

A wood pellet mill that can continue to work without failure, guarantee output, and win profits is a good equipment, when the value is equal to or greater than the price of the wood pellet machine.

Then the most expensive equipment is not expensive, and the main factor that determines the wood pellet machine price is the strength of the manufacturer. Plant area, processing accuracy, spare parts supply, after-sales service, etc. are collectively referred to as manufacturer strength.

Customers with long-term goals will spend more on good, high-value wood pellet mill plant equipment than on low-value bargains. Again, seeing is believing, it is strongly recommended that all bosses must come out and turn to the manufacturer to see the strength of the manufacturer to know whether the wood pellet mill price is more important or the value is more important. (Related post:biomass wood pellet plant in Indonesia )

If you want to know more about new condition wood pellet mill for sale USA, Europe use wood pellet mill for sale Austria, new technology 2-3 ton per hour wood pellet mill for sale Australia, wood sawdust biomass wood pellet mill for sale Indonesia, wood pellet mill for sale Malaysia, wood pellet mill for sale Thailand, wood pellet mill for sale Netherlands, please contact Richi Machinery for details.