As we strive for more sustainable and eco-friendly energy sources, pellet stoves have become an increasingly popular and efficient home heating solution. These stoves use pellets made from compressed biomass materials, such as wood, agricultural residues, and other organic matter, providing a clean and renewable source of heat. At the core of this innovation is the pellet stove pellet making machine, a specialized piece of equipment that produces the high-quality pellets needed to fuel these stoves. This article explores the benefits, working principles, and considerations when investing in a pellet stove pellet making machine.

The Rise of Pellet Stoves: A Sustainable Heating Solution

Pellet stoves have gained traction recently due to growing environmental awareness and the need to reduce fossil fuel dependence. They offer several advantages over traditional heating methods:

- Renewable Energy Source: Pellets are made from renewable biomass materials like sawdust, wood shavings, and agricultural residues, making them a sustainable fuel option.

- High Efficiency: Pellet stoves are designed to burn pellets efficiently, providing consistent heat output with minimal waste, leading to lower heating costs and reduced environmental impact.

- Low Emissions: Burning pellets produces fewer particulate emissions and greenhouse gases compared to fossil fuels, resulting in cleaner air and a smaller carbon footprint.

- Convenience and Ease of Use: Pellet stoves feature automated feeding systems that ensure a steady supply of pellets to the combustion chamber, making them user-friendly.

- Versatility: Suitable for various settings, including homes, cabins, and small commercial spaces, pellet stoves are versatile heating solutions.

The Role of Pellet Stove Pellet Making Machines

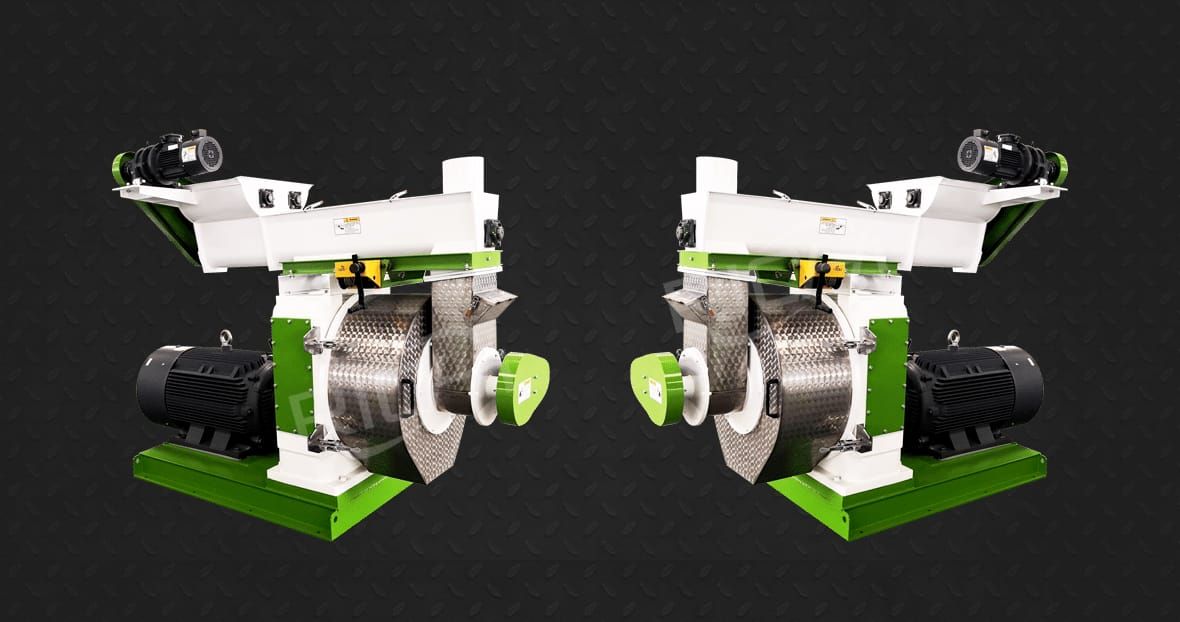

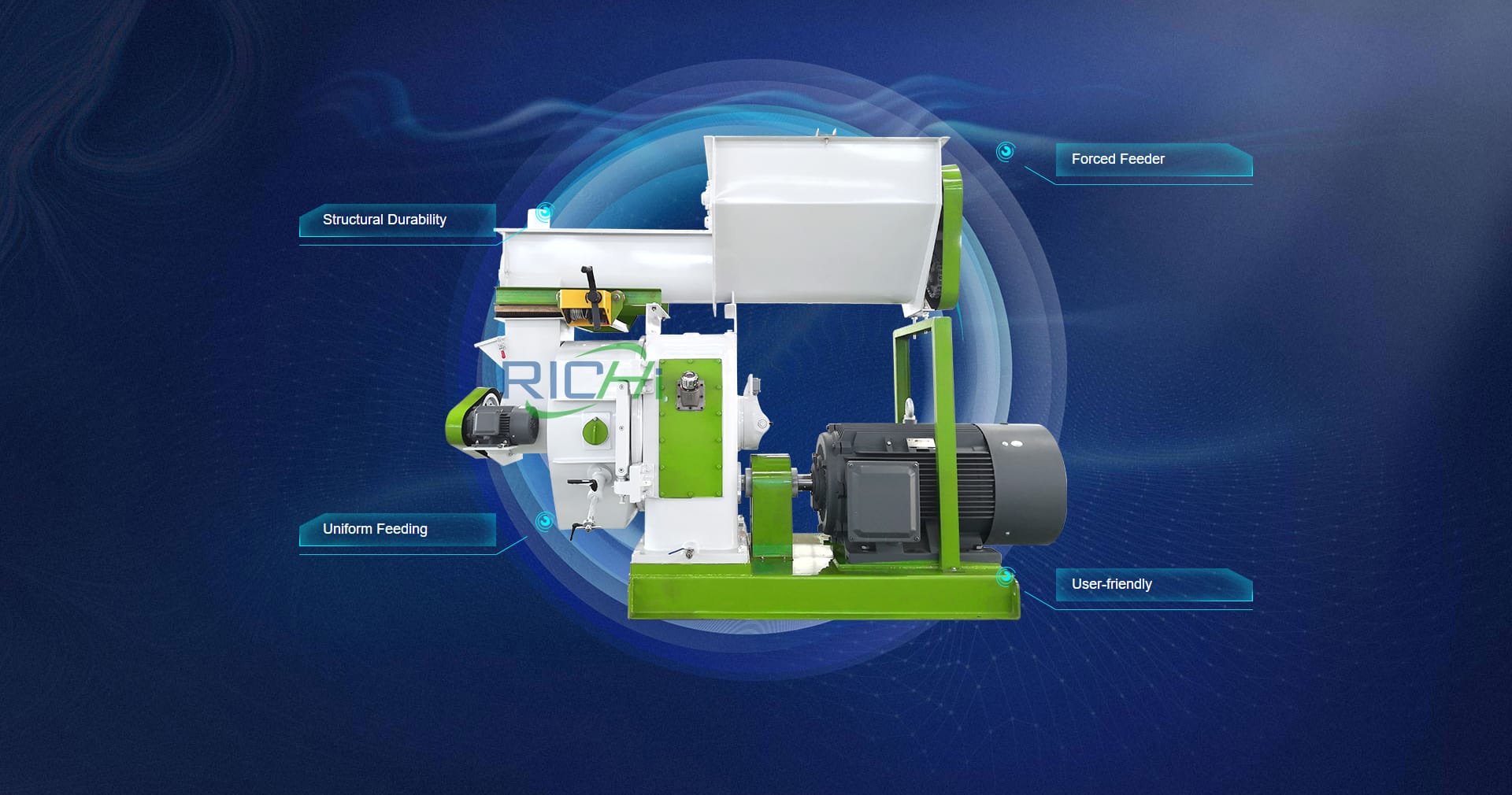

Pellet stove pellet making machines are crucial for producing the high-quality pellets that fuel pellet stoves. These machines compress raw biomass materials into dense, uniform pellets, ensuring consistent combustion and heat output. The pellet-making process involves several stages:

- Raw Material Preparation: Collect and sort biomass materials like sawdust and wood shavings, then dry them to reduce moisture content.

- Grinding and Sizing: Feed dried materials into a grinding mill to achieve a consistent particle size, essential for uniform pellet quality.

- Conditioning: Condition the ground material with steam or water to soften it, making compression easier.

- Pelleting: Compress and extrude the conditioned material through die holes using rollers or a ring die, then cut the pellets to the desired length.

- Cooling and Drying: Rapidly cool and dry the hot pellets to maintain their structural integrity.

- Screening and Packaging: Screen the pellets to remove fines or oversized pieces, then package them for storage and distribution.

Benefits of Pellet Stove Pellet Making Machines

Investing in a pellet stove pellet making machine offers several benefits:

- Cost Savings: Producing your own pellets can significantly reduce heating costs compared to buying pre-made pellets.

- Control Over Quality: Self-producing pellets allows you to ensure consistent quality and composition, enhancing stove performance.

- Sustainability: Using locally sourced biomass reduces transportation-related environmental impact and supports sustainable land management.

- Versatility: These machines can process a variety of biomass materials, providing flexibility in feedstock selection.

- Entrepreneurial Opportunities: Small businesses can produce and sell high-quality pellets, creating new revenue streams.

Factors to Consider When Investing in a Pellet Stove Pellet Making Machine

When purchasing a pellet stove pellet making machine, consider these factors:

- Production Capacity: Choose a machine that matches your heating needs and future growth plans. Higher capacity machines require larger investments but offer economies of scale.

- Feedstock Availability and Quality: Ensure a consistent and reliable supply of high-quality biomass feedstock.

- Machine Type and Specifications: Evaluate different types of pellet making machines (e.g., flat die vs. ring die) for efficiency, automation, and ease of maintenance.

- Energy Consumption: Assess the machine’s energy requirements and ensure your facility can meet them. Energy-efficient machines reduce operational costs.

- Cost and Financing: Conduct a thorough financial analysis and explore financing options to manage upfront costs.

- Supplier Reputation and Support: Choose a reputable supplier who offers training, technical support, and maintenance services to ensure optimal machine performance.

The Future of Pellet Stove Pellet Making Machines

As global demand for renewable energy rises, pellet stove pellet making machines will become increasingly important for sustainable home heating solutions. Advances in biomass processing technologies, alternative feedstock sources, and automation will enhance these machines’ efficiency and effectiveness.

Investing in a pellet stove pellet making machine allows homeowners, small businesses, and entrepreneurs to reduce heating costs and environmental impact while contributing to a cleaner, more sustainable energy future. These machines empower individuals and communities to embrace renewable energy solutions, paving the way for a greener, more resilient world.

Related post: https://www.richipelletmachine.com/pellet-line-for-sale/