Biomass pellet presses are critical equipment used to convert various types of biomass materials, such as agricultural residues and wood waste, into high-density fuel pellets. The efficiency, durability, and overall performance of these presses are heavily influenced by the quality and suitability of their accessories. Selecting the right accessories not only enhances the production process but also plays a significant role in determining the maintenance costs associated with operating a biomass pellet press. This article explores how accessory selection impacts the maintenance costs of biomass pellet presses and provides insights into making informed choices.

1. Importance of Feeder Selection

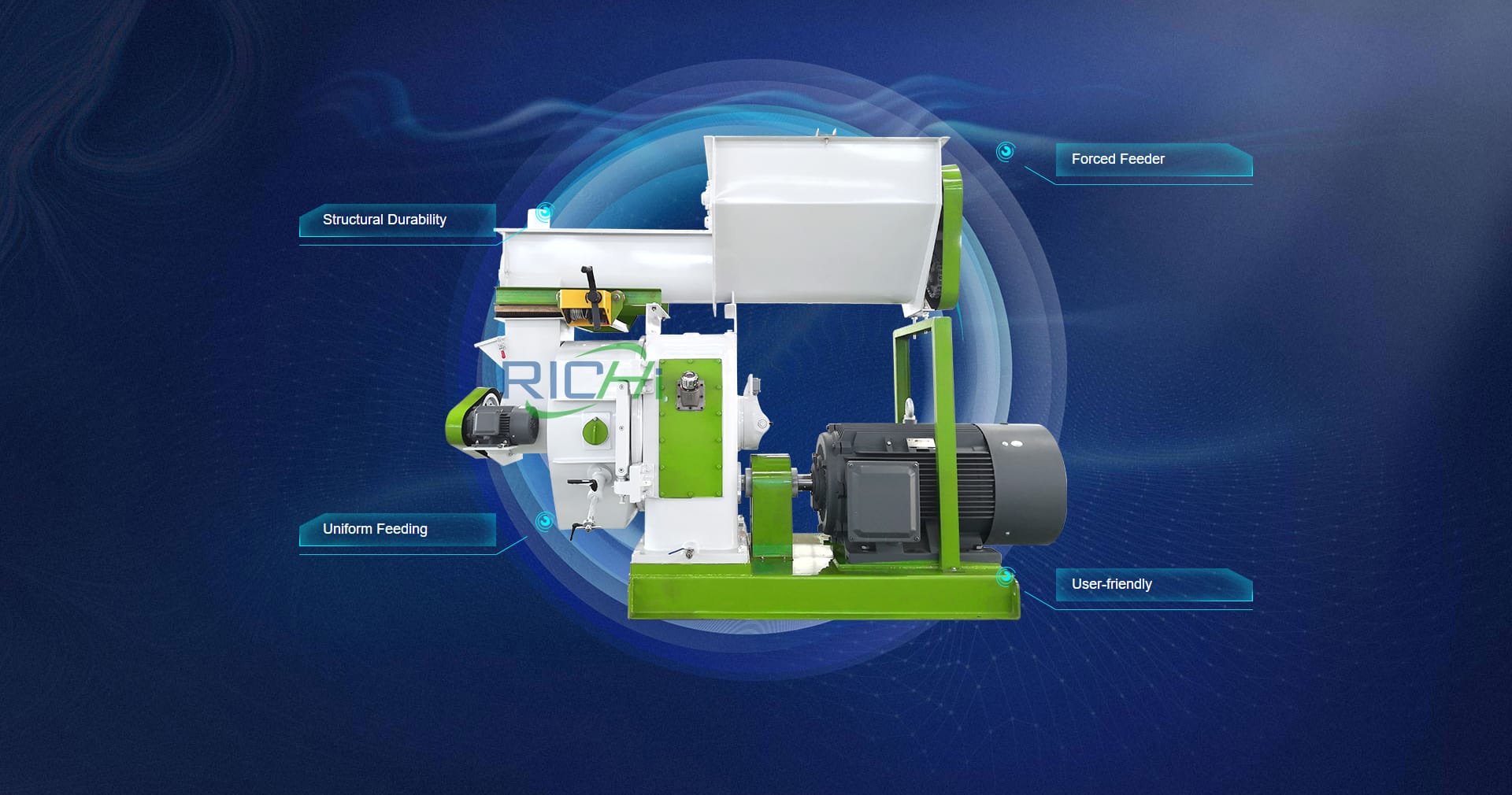

The feeder is responsible for delivering a consistent flow of raw materials into the pellet press. The quality and design of the feeder can significantly impact maintenance costs.

- Durability: Feeders made from durable, wear-resistant materials can withstand the abrasive nature of biomass materials, reducing the frequency of replacements and maintenance. This directly translates to lower maintenance costs over time.

- Flow Control: A well-designed feeder provides accurate and consistent material flow, preventing fluctuations that can lead to operational issues and increased maintenance requirements. Inconsistent feeding can cause pressure variations in the pellet chamber, affecting pellet quality and leading to more frequent maintenance.

2. Crushing System Quality

The crushing system is used to reduce the size of biomass materials before they enter the pellet press. The efficiency and quality of the crushing process can impact maintenance costs.

- Particle Size: Selecting a crusher that can consistently produce the desired particle size (typically less than 5 mm) for optimal pelleting is crucial. If the material is too large, it may not compact properly, leading to weak pellets and increased wear on the pellet press components.

- Maintenance Requirements: Choosing a crusher with low maintenance needs can significantly reduce downtime and associated maintenance costs. Regular maintenance of the crusher will also prolong its lifespan and ensure consistent performance, minimizing the need for frequent repairs or replacements.

3. Die and Roller Quality

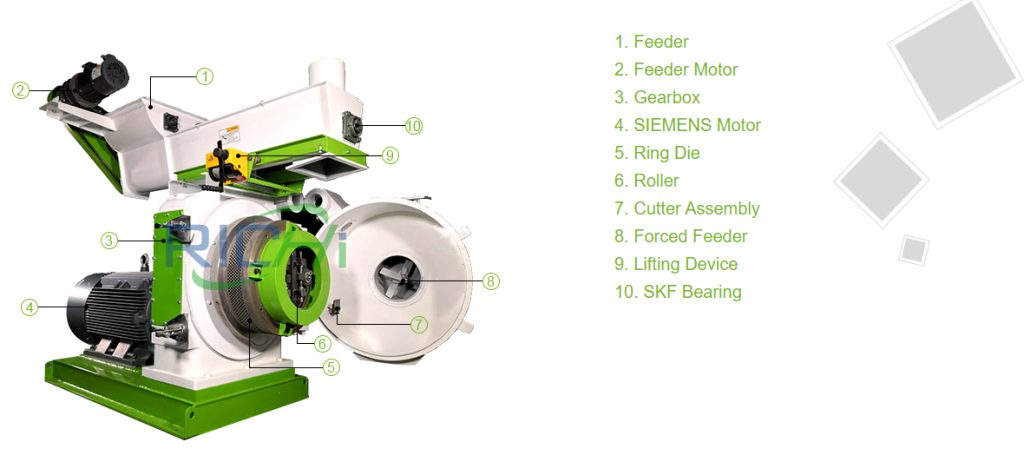

The die and rollers are critical components of the Biomass Granulator, responsible for shaping the pellets. Their quality directly impacts the efficiency, durability, and maintenance costs of the machine.

- Material Selection: Dies and rollers should be made from high-quality, wear-resistant materials to withstand the high pressures and temperatures during pelleting. Poor-quality components can lead to frequent replacements and increased maintenance costs.

- Precision Engineering: The precision of the die and roller design is crucial for ensuring consistent pellet size and density. Inaccurate components can lead to uneven pellet formation, affecting the overall quality and performance of the machine, which may necessitate more frequent maintenance.

4. Cooling System Efficiency

The cooling system is essential for stabilizing the pellets after they are formed. Proper cooling is vital for maintaining pellet quality and preventing spoilage, which can impact maintenance costs.

- Cooling Efficiency: High-quality cooling systems effectively reduce the temperature of the pellets while minimizing moisture loss. This is crucial for maintaining the structural integrity of the pellets and ensuring they are ready for packaging. Inefficient cooling can lead to issues with pellet quality and increased maintenance requirements.

- Impact on Production Rate: An efficient cooling system helps prevent bottlenecks in the production process, allowing for a smoother workflow and higher overall output. Delays in cooling can lead to increased maintenance costs due to downtime and potential issues with pellet quality.

5. Selecting Quality Accessories

Investing in high-quality accessories can significantly reduce maintenance costs over the long term. When selecting accessories, consider the following factors:

- Supplier Reputation: Choose accessories from reputable suppliers known for their quality and reliability. Researching suppliers and reading reviews can help ensure that you are investing in durable components that require less maintenance.

- Compatibility: Ensure that the accessories are compatible with the specific model of the biomass pellet press. Incompatible components can lead to operational issues, reduced efficiency, and increased maintenance requirements.

- Warranty and Support: Look for suppliers that offer warranties and after-sales support for their products. This can provide peace of mind and assistance in case of any issues that arise during operation, potentially reducing maintenance costs.

6. Long-Term Cost Savings

Investing in high-quality accessories can lead to substantial long-term cost savings in terms of maintenance:

- Reduced Maintenance Frequency: Durable, well-designed accessories require less frequent maintenance, leading to lower labor costs and fewer production interruptions over time.

- Extended Equipment Lifespan: Quality accessories can prolong the lifespan of the biomass pellet press, reducing the need for costly replacements and ensuring a better return on investment.

- Improved Production Efficiency: Efficient accessories contribute to higher production rates and better pellet quality, which can lead to increased revenue and profitability. This, in turn, can offset the initial investment in quality accessories.

7. Conclusion

The selection of accessories for biomass pellet presses plays a critical role in determining their long-term maintenance costs and overall performance. By focusing on the quality of feeders, crushers, dies and rollers, and cooling systems, producers can optimize their pellet production processes and ensure consistent, high-quality output while minimizing maintenance expenses.Investing in high-quality accessories and maintaining them properly will contribute to the overall success and sustainability of biomass pellet production operations. As the demand for renewable energy sources continues to grow, prioritizing the selection of quality components will be essential for maintaining a competitive edge in the market. By understanding the importance of accessory selection and its impact on maintenance costs, producers can enhance the longevity and efficiency of their biomass pellet presses, ultimately leading to greater profitability and sustainability in their operations.