Wood pellet machines are essential in the production of wood pellets, which serve as a renewable and efficient fuel source. These machines are designed to process various raw materials into pellets and are widely used in wood pellet factories. This article explores the raw materials that wood pellet machines can process, their applications in pellet factories, how to buy a wood pellet machine, the advantages of ring die pellet mills, their suitability for different factories, how to choose a commercial wood pellet machine, and the benefits of RICHI wood pellet machines.

What Raw Materials Can Wood Pellet Machines Process?

Wood pellet machines are versatile and can handle a range of raw materials. Understanding these materials is crucial for optimizing pellet production. Here’s a look at the primary raw materials:

1. Wood Chips and Sawdust

Wood chips and sawdust are the most common raw materials used in wood pellet production. These by-products from woodworking and lumber industries are readily available and can be processed into high-quality pellets. Wood chips are typically pre-treated to ensure they meet the size and moisture requirements for pelletizing.

2. Wood Shavings

Wood shavings, often a by-product from planing or shaping wood, can be used to produce wood pellets. They are finer than wood chips and may require grinding or conditioning before pelletizing to achieve the desired pellet quality.

3. Agricultural Residues

In addition to wood, agricultural residues such as straw, corn stalks, and wheat bran can be used in wood pellet machines. These materials are processed similarly to wood by grinding, conditioning, and pelletizing, offering an alternative to traditional wood sources.

4. Sawdust and Shavings from Bamboo and Other Biomass

Sawdust and shavings from bamboo or other biomass materials can also be processed into pellets. These materials are often used in regions where traditional wood sources are limited, and they provide an additional feedstock for pellet production.

Application of Wood Pellet Machine in Wood Pellet Plants

Wood pellet machines play a crucial role in wood pellet factories, enabling the production of high-quality pellets for various applications. Here’s how they are applied in these factories:

1. Fuel Production

One of the primary applications of wood pellet machines in factories is the production of wood pellets as a renewable energy source. These pellets are used as fuel for heating and power generation, offering a sustainable alternative to fossil fuels.

2. Animal Bedding

Wood pellets are also used as bedding material for livestock and pets. In pellet factories, wood pellet machines produce pellets that are absorbent, low-dust, and comfortable for animals, improving their living conditions.

3. Biomass Energy Generation

Wood pellet plants may also use the pellets they produce for biomass energy generation. The pellets are burned in specialized boilers to produce heat and electricity, contributing to the reduction of greenhouse gas emissions and reliance on non-renewable energy sources.

4. Export and Commercial Sales

Pellet factories often produce pellets for commercial sale and export. Wood pellet machines help factories meet the demands of domestic and international markets by producing pellets with consistent quality and specifications.

How to Buy a Wood Pellet Machine

Purchasing a wood pellet machine requires careful consideration of several factors to ensure that the chosen equipment meets your production needs. Here’s a guide to help you through the process:

1. Assess Production Requirements

Determine your production capacity requirements, including the volume of pellets you need to produce and the type of raw materials you will be processing. This will help you select a machine with the appropriate capacity and features.

2. Research Machine Specifications

Research different wood pellet machines and compare their specifications. Look for features such as pellet size adjustment, energy efficiency, and ease of maintenance. Understanding the specifications will help you choose a machine that fits your production needs.

3. Evaluate Manufacturer Reputation

Select a wood pellet machine from a reputable manufacturer with a proven track record of producing high-quality equipment. Consider customer reviews, testimonials, and the manufacturer’s support services.

4. Request Quotes and Financing Options

Contact manufacturers or distributors to request quotes for the models you are interested in. Inquire about financing options, if available, to help manage the cost of the machine.

5. Consider After-Sales Support

Ensure that the manufacturer or distributor offers comprehensive after-sales support, including maintenance services, spare parts, and technical assistance. Good after-sales support is essential for the long-term performance of the machine.

What Are the Advantages of Ring Die Pellet Mill?

Ring die pellet mills are a popular choice in wood pellet production due to their efficiency and performance. Here are some of the key advantages:

1. High Production Capacity

Ring die pellet mills are known for their high production capacity, making them suitable for large-scale pellet production. They can handle large volumes of raw materials and produce pellets at a high rate, increasing overall productivity.

2. Consistent Pellet Quality

The ring die design ensures uniform pellet size and density, resulting in consistent pellet quality. This consistency is important for meeting the specifications required for different applications and maintaining the quality of the final product.

3. Energy Efficiency

Ring die pellet mills are designed to be energy-efficient, reducing the amount of energy required for pelletizing. This efficiency helps lower operational costs and makes the production process more cost-effective.

4. Versatility

Ring die pellet mills are versatile and can process a wide range of raw materials, including wood, agricultural residues, and biomass. This flexibility allows manufacturers to adapt to different feedstocks and market demands.

5. Durability and Longevity

The robust construction of ring die pellet mills ensures durability and long-term performance. These machines are built to withstand the demands of continuous operation and handle various types of raw materials.

Which Factories Are Ring Die Pellet Mills Suitable For?

Ring die pellet mills are suitable for various types of factories based on their production needs and scale:

1. Large-Scale Pellet Factories

Ring die pellet mills are ideal for large-scale pellet factories that require high production capacity and consistent pellet quality. These factories benefit from the efficiency and productivity of ring die machines, making them suitable for large volumes of production.

2. Biomass Energy Plants

Biomass energy plants that generate heat and electricity from wood pellets and other biomass materials can utilize ring die pellet mills to produce high-quality pellets. The machines’ efficiency and versatility are well-suited for meeting the demands of biomass energy generation.

3. Animal Feed Production Facilities

Facilities that produce animal feed, including bedding material for livestock and pets, can benefit from ring die pellet mills. The machines’ ability to produce consistent and durable pellets ensures that the feed meets the required specifications for different animals.

4. Export and Commercial Pellet Manufacturers

Ring die pellet mills are suitable for manufacturers who produce pellets for commercial sale and export. The machines’ high production capacity and quality control features help meet the demands of domestic and international markets.

How to Choose a Commercial Wood Pellet Machine

Selecting the right commercial wood pellet machine involves considering several key factors:

1. Production Capacity

Determine the production capacity required for your operation, including the volume of pellets you need to produce daily or annually. Choose a machine that can meet your production needs while maintaining efficiency.

2. Raw Material Compatibility

Ensure that the wood pellet machine can handle the types of raw materials you plan to process. Check the machine’s specifications for compatibility with wood chips, sawdust, agricultural residues, and other materials.

3. Pellet Quality

Evaluate the machine’s ability to produce pellets of consistent size and quality. Look for features such as adjustable pellet size settings and quality control mechanisms to ensure that the pellets meet your standards.

4. Energy Efficiency

Consider the energy efficiency of the machine, as this will impact your operational costs. Choose a machine that offers high performance while minimizing energy consumption.

5. Durability and Maintenance

Select a machine with a robust construction and reliable performance. Look for models that offer easy maintenance and access to spare parts to ensure long-term operation and reduce downtime.

6. Manufacturer Support

Choose a machine from a reputable manufacturer that offers comprehensive support, including installation, training, and after-sales service. Good support is crucial for maintaining the machine’s performance and addressing any issues that arise.

What Are the Advantages of RICHI Wood Pellet Machine?

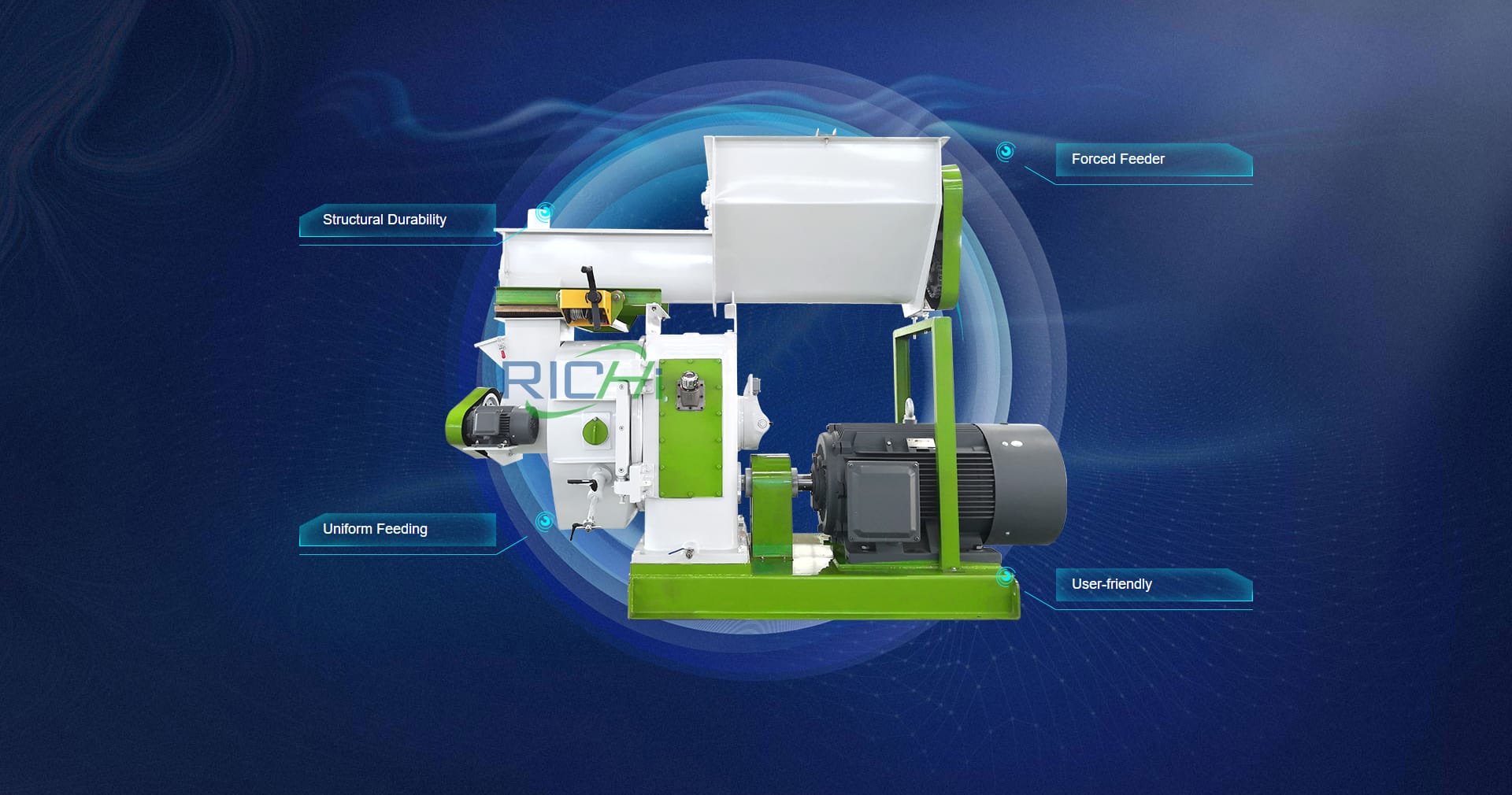

RICHI Machinery is known for producing high-quality wood pellet machines with several advantages:

1. Advanced Technology

RICHI wood pellet machines incorporate advanced technology that enhances efficiency, pellet quality, and overall performance. The machines use cutting-edge designs and features to optimize the pelletizing process.

2. Customizable Options

RICHI offers customizable options for pellet size, density, and production capacity, allowing you to tailor the machine to your specific needs. This flexibility ensures that the machine meets your production requirements and quality standards.

3. Energy Efficiency

RICHI machines are designed for energy efficiency, reducing operational costs and improving cost-effectiveness. The machines use energy-efficient components and technology to maximize performance while minimizing energy consumption.

4. Durable Construction

RICHI wood pellet machines are built with high-quality materials and robust construction, ensuring durability and long-term performance. The machines are designed to withstand the demands of continuous operation and handle various raw materials.

5. User-Friendly Operation

RICHI machines feature user-friendly controls and interfaces, making them easy to operate and manage. This ease of use reduces the need for extensive training and allows for efficient production.

6. Comprehensive Support

RICHI provides excellent after-sales support, including installation, training, and technical assistance. This support helps ensure that your machine operates smoothly and efficiently throughout its lifespan.

Conclusion

Wood pellet machines are vital in the production of wood pellets, offering benefits such as efficient processing, consistent pellet quality, and versatility in handling various raw materials.