Feed Pellet Machine: An Overview

Feed pellet machines are essential equipment in modern animal husbandry and agriculture. These machines convert raw feed ingredients into uniform pellets, which are crucial for efficient and effective animal nutrition. This article provides a comprehensive overview of feed pellet machines, their applications, the features of RICHI feed pellet machines, the types of animal feed they can process, and guidance on purchasing and evaluating their quality and price.

Application of Feed Pellet Machine

Feed pellet machines are versatile tools used across various sectors of animal farming. Their primary applications include:

1. Livestock Feeding

Feed pellet machines are extensively used to produce pellets for livestock such as cattle, sheep, and goats. Pellets ensure that these animals receive a balanced diet with consistent nutrient distribution, which is crucial for their growth, milk production, and overall health.

2. Poultry Feed Production

In poultry farming, feed pellet machines are used to manufacture feed for chickens, turkeys, ducks, and other birds. Pellets enhance feed intake efficiency and reduce feed waste. They also make it easier to include supplements and additives that improve poultry health and productivity. Related: Poultry Feed Pellet Mill

3. Aquaculture

Aquaculture operations use fish feed pellet machines to produce fish and shrimp feed. The ability to control pellet size and composition helps meet the specific dietary needs of various aquatic species, improving growth rates and feed conversion ratios.

4. Pet Food Manufacturing

Feed pellet machines are also employed in the production of pet food, including for dogs, cats, and other pets. Pellets ensure uniformity in pet food, making it easier to deliver balanced nutrition and accommodate different dietary requirements.

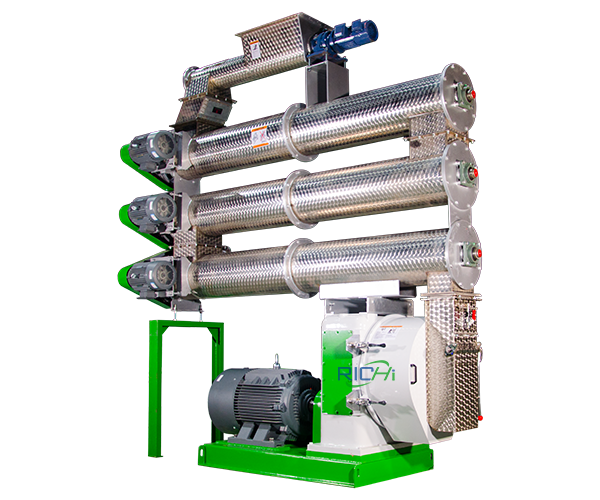

RICHI Feed Pellet Machine Features

RICHI Machinery is a leading manufacturer of feed pellet machines, known for their high-quality and reliable equipment. Here are some notable features of RICHI feed pellet machines:

1. Advanced Pelletizing Technology

RICHI feed pellet machines incorporate advanced pelletizing technology that ensures efficient processing of feed ingredients. The machines use high pressure and temperature to produce durable and uniform pellets, which enhances feed quality and reduces wastage.

2. Customizable Pellet Size and Density

RICHI machines offer customizable options for pellet size and density, allowing users to adjust settings based on the specific requirements of different animals. This flexibility ensures that the feed meets the nutritional needs and preferences of various livestock and poultry.

3. Robust Construction

RICHI feed pellet machines are built with high-quality materials and robust construction, ensuring durability and long-term performance. The machines are designed to withstand the demands of continuous operation and handle a wide range of feed ingredients.

4. User-Friendly Operation

The user-friendly design of RICHI feed pellet machines includes intuitive controls and interfaces that simplify operation. This ease of use reduces the need for extensive training and allows operators to efficiently manage the pelletizing process.

5. Efficient Energy Consumption

RICHI machines are engineered for energy efficiency, helping to lower operational costs. They are designed to minimize energy consumption while maintaining high production output, making them cost-effective for large-scale feed production.

6. Easy Maintenance

Maintenance is simplified with RICHI feed pellet machines, thanks to accessible components and straightforward maintenance procedures. Regular maintenance helps ensure the machine’s longevity and consistent performance.

What Animal Feed Can the Feed Pellet Machine Process?

Feed pellet machines are versatile and can process a wide variety of feed ingredients, making them suitable for different types of animal feed. Some common types of animal feed processed by these machines include:

1. Cereal Grains

Cereal grains such as corn, wheat, barley, and oats are commonly used in feed production. Pellet machines can process these grains into pellets, providing a consistent and energy-dense feed for livestock and poultry.

2. Protein Meals

Protein meals, including soybean meal, canola meal, and fish meal, are essential components of animal feed. Pellet machines efficiently incorporate these protein sources into pellets, ensuring that animals receive the necessary protein for growth and development.

3. Forage and Hay

Pellets made from forage crops and hay, such as alfalfa or clover, are used to provide fiber and nutrients to livestock. Pelletizing these materials improves their digestibility and makes them easier to handle and store.

4. By-Products and Additives

Feed pellet machines can also process various by-products and additives, including molasses, vitamins, minerals, and other supplements. This allows for the creation of nutritionally balanced and customized feed formulations.

5. Specialty Feeds

For specific needs, such as aquaculture or pet food, pellet machines can produce specialty feeds tailored to the dietary requirements of fish, shrimp, and pets. The ability to control pellet size and composition is crucial for optimizing feed performance in these applications.

How to Buy a Feed Pellet Machine

Purchasing a feed pellet machine requires careful consideration to ensure you select the right equipment for your needs. Here’s a guide to help you through the buying process:

1. Assess Your Production Needs

Start by evaluating your feed production requirements, including the type of feed you need to process, the desired pellet size, and the expected production volume. This assessment will help you choose a machine with the appropriate capacity and features.

2. Research Different Models

Research various feed pellet machines available in the market. Consider factors such as machine capacity, pellet size options, and additional features. Compare different models from reputable manufacturers, including RICHI, to find one that matches your requirements.

3. Consider Energy Efficiency

Energy efficiency is a critical factor in the overall cost of operating a feed pellet machine. Look for machines that offer efficient energy consumption to reduce operating costs and improve profitability.

4. Evaluate Manufacturer Reputation

Choose a feed pellet machine from a reputable manufacturer with a track record of producing high-quality equipment. Consider customer reviews, testimonials, and the manufacturer’s support services when making your decision.

5. Request Quotes and Financing Options

Contact manufacturers or distributors to request quotes for the models you’re interested in. Inquire about financing options, if available, to help manage the cost of the machine.

6. Review After-Sales Support

Ensure that the manufacturer or distributor offers comprehensive after-sales support, including maintenance services, spare parts, and technical assistance. Good after-sales support is essential for the long-term performance and reliability of the machine.

7. Make an Informed Purchase

Once you’ve gathered all the necessary information, make an informed decision based on your production needs, budget, and the features of the machine. Place your order and arrange for installation and training if needed.

Quality and Price of RICHI Machinery’s Feed Pellet Machine

RICHI Machinery is known for producing high-quality feed pellet machines that offer durability, efficiency, and performance. The price of RICHI feed pellet machines varies depending on factors such as the model, capacity, and customization options. Generally, the price ranges from a few thousand dollars for smaller models to tens of thousands of dollars for larger, industrial-scale machines.

When evaluating the quality and price of RICHI feed pellet machines, consider the following:

1. Build Quality

RICHI machines are constructed from high-quality materials that ensure durability and long-term performance. The robust construction contributes to the machine’s ability to handle demanding feed production tasks.

2. Technological Advancements

RICHI incorporates advanced technology in its pellet machines, which enhances efficiency and pellet quality. The use of modern technology may influence the price, but it also ensures superior performance.

3. Cost-Effectiveness

While the initial cost of RICHI feed pellet machines may be higher compared to some competitors, the long-term benefits, including energy savings, reduced maintenance costs, and increased production efficiency, often make them a cost-effective choice.

4. Warranty and Support

RICHI offers warranties and after-sales support, which add value to your purchase. The availability of technical support and replacement parts ensures that your machine remains in optimal condition throughout its lifespan.

Conclusion

Feed pellet machines play a vital role in modern animal feed production, offering benefits such as improved nutritional delivery, convenience, and versatility. RICHI Machinery is a leading provider of high-quality feed pellet machines, known for their advanced features and reliable performance. By understanding the applications, features, and purchasing considerations, you can make an informed decision when selecting a feed pellet machine that meets your production needs and budget. Whether you’re producing feed for livestock, poultry, aquaculture, or pets, investing in a quality feed pellet machine will enhance your operations and contribute to better animal health and productivity.