Establishing a 2 tons per hour (T/H) wood pellet production line in France presents a significant opportunity due to the country’s commitment to renewable energy and its ample forest resources. Here’s a comprehensive guide to setting up such a facility, taking into account French regulations and market demands.

1. Project Planning and Feasibility Study

Steps:

- Market Analysis: Assess the demand for wood pellets in France and potential export markets. Consider factors such as competitive landscape, pricing, and target customers.

- Raw Material Assessment: Evaluate the availability of raw materials such as sawdust, wood shavings, and wood chips. Analyze the supply chain logistics and reliability.

- Location Evaluation: Choose a location based on proximity to raw materials and target markets. Consider transportation infrastructure and logistical aspects.

- Financial Projections: Develop detailed financial projections, including capital expenditure, operating costs, and expected ROI.

- Regulatory Review: Conduct environmental impact assessments and review relevant regulations and permits.

2. Site Selection and Preparation

Steps:

- Site Selection: Ensure the site complies with zoning laws and local regulations. Consider environmental and community impacts.

- Permits and Approvals: Obtain necessary permits and approvals from French authorities, including environmental permits.

- Site Preparation: Prepare the site by clearing and leveling the land, and developing basic infrastructure such as roads and utilities.

3. Facility Design and Engineering

Steps:

- Production Line Layout: Develop a detailed layout of the production line, including placement of equipment and workflow.

- Building and Foundations: Design engineering plans for buildings and equipment foundations, adhering to French building codes.

- Utility Systems: Design and plan for electrical, water, and compressed air systems.

- Compliance: Incorporate French safety standards and environmental regulations into the design.

4. Equipment Selection and Procurement

Essential Equipment:

- Raw Material Handling: Systems for receiving, storing, and conveying raw materials.

- Drying Equipment: For processing green wood, consider rotary dryers or other suitable drying systems.

- Grinding/Milling Machinery: Hammer mills or similar equipment for reducing wood to the required size.

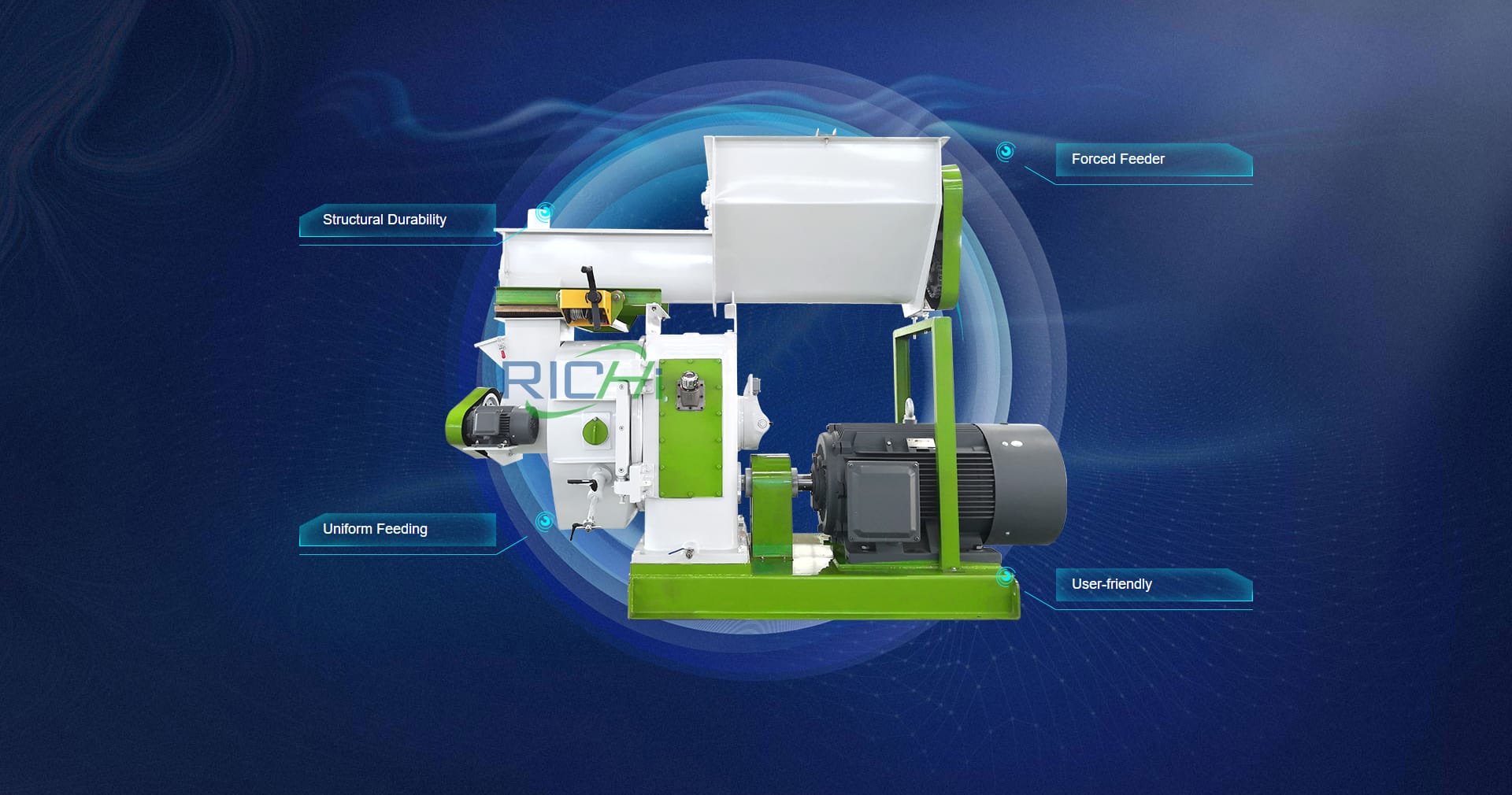

- Pelletizing Presses: High-capacity pellet mills for compressing raw material into pellets.

- Cooling Systems: Counterflow coolers or other cooling systems to stabilize the pellets.

- Screening and Quality Control: Equipment for sorting and ensuring pellet quality.

- Packaging Systems: Automated systems for efficient packaging of finished pellets.

Considerations:

- Ensure equipment meets French electrical standards (230V/50Hz) and EU machinery directives.

- Prioritize energy efficiency and scalability.

5. Construction and Installation

Steps:

- Building Construction: Erect or modify buildings to house the production equipment.

- Equipment Installation: Install and set up all production equipment.

- Utility Connections: Connect utility systems such as electricity and water.

- Safety Systems: Implement dust control, fire safety, and other necessary safety measures.

6. Raw Material Sourcing and Preparation

Steps:

- Supply Chain Agreements: Establish contracts with local sawmills and forestry companies for a reliable raw material supply.

- Storage and Processing: Set up facilities for raw material storage and preliminary processing.

Sustainability:

- Ensure raw materials meet sustainability criteria, as this is important for the French market.

7. Process Integration and Optimization

Steps:

- Material Flow Setup: Integrate the production line components for smooth material flow from reception to packaging.

- Equipment Calibration: Adjust and calibrate equipment for optimal performance.

- Quality Control: Implement quality control measures at different stages of production.

- Certification: Ensure compliance with French and EU pellet quality standards (e.g., ENplus certification).

8. Automation and Control Systems

Steps:

- Control System: Install sensors and monitoring equipment for process control.

- Central Control Room: Set up a control room for managing the production process.

- Management Software: Implement production management software for efficiency and monitoring.

Compliance:

- Ensure systems comply with French data protection and industrial automation standards.

9. Testing and Commissioning

Steps:

- Equipment Testing: Conduct thorough testing of equipment and systems.

- Trial Runs: Perform trial runs to ensure product quality meets French standards.

- Certification: Obtain necessary certifications for the facility and products.

- Staff Training: Train staff on equipment operation and safety procedures.

10. Environmental Compliance and Sustainability Measures

Steps:

- Dust Collection: Implement dust collection and air filtration systems.

- Wastewater Treatment: Set up facilities for wastewater treatment if required.

- Energy Management: Establish systems to optimize energy use and consider renewable energy options like solar panels.

11. Quality Assurance and Certification

Steps:

- Quality Control: Implement rigorous quality control procedures.

- Certifications: Obtain ENplus certification for wood pellets and consider additional certifications like ISO 9001 for quality management.

12. Logistics and Distribution Planning

Steps:

- Storage Facilities: Set up storage for finished products.

- Transportation: Establish relationships with transportation companies for distribution.

- Market Distribution: Plan for both domestic French market and potential exports to other EU countries.

13. Marketing and Customer Relations

Steps:

- Marketing Strategy: Develop strategies tailored to the French market.

- Customer Service: Set up protocols for customer service and support.

- Order Processing: Implement systems for efficient order processing and fulfillment.

14. Compliance with French Labor Laws

Steps:

- Employment Practices: Ensure compliance with French labor regulations regarding work schedules and breaks.

- Health and Safety: Implement necessary health and safety measures, and provide training and PPE for staff.

15. Ongoing Monitoring and Improvement

Steps:

- Efficiency Assessment: Regularly assess production efficiency and product quality.

- Regulation Updates: Stay updated on changes in French and EU regulations.

- Sustainability Improvements: Continuously explore ways to reduce environmental impact and improve sustainability.

Conclusion

Building a 2 T/H wood pellet production line in France involves a comprehensive approach, addressing both technical and regulatory aspects. By carefully planning each phase—from feasibility studies to ongoing operations—this project can effectively contribute to France’s renewable energy goals while meeting market demands. Success relies on thorough preparation, adherence to quality standards, and commitment to sustainability, aligning well with France’s environmental and energy policies.