Italy, with its thriving furniture industry and growing focus on renewable energy, presents an excellent opportunity for establishing a sawdust pellet production line. A 1-2 tons per hour (T/H) capacity plant is ideal for small to medium-sized operations, often integrated with existing wood processing facilities. This article outlines the essential equipment required for such a production line and provides estimated costs based on current market trends.

Key Equipment for a 1-2 T/H Sawdust Wood Pellet Production Line

- Raw Material Handling System

- Conveyor belts

- Storage bins

Estimated cost: €15,000 – €25,000

- Drying System

- Rotary drum dryer

Estimated cost: €50,000 – €80,000

- Rotary drum dryer

- Hammer Mill

For grinding larger wood particles into fine sawdust

Estimated cost: €20,000 – €30,000 - Pellet Mill

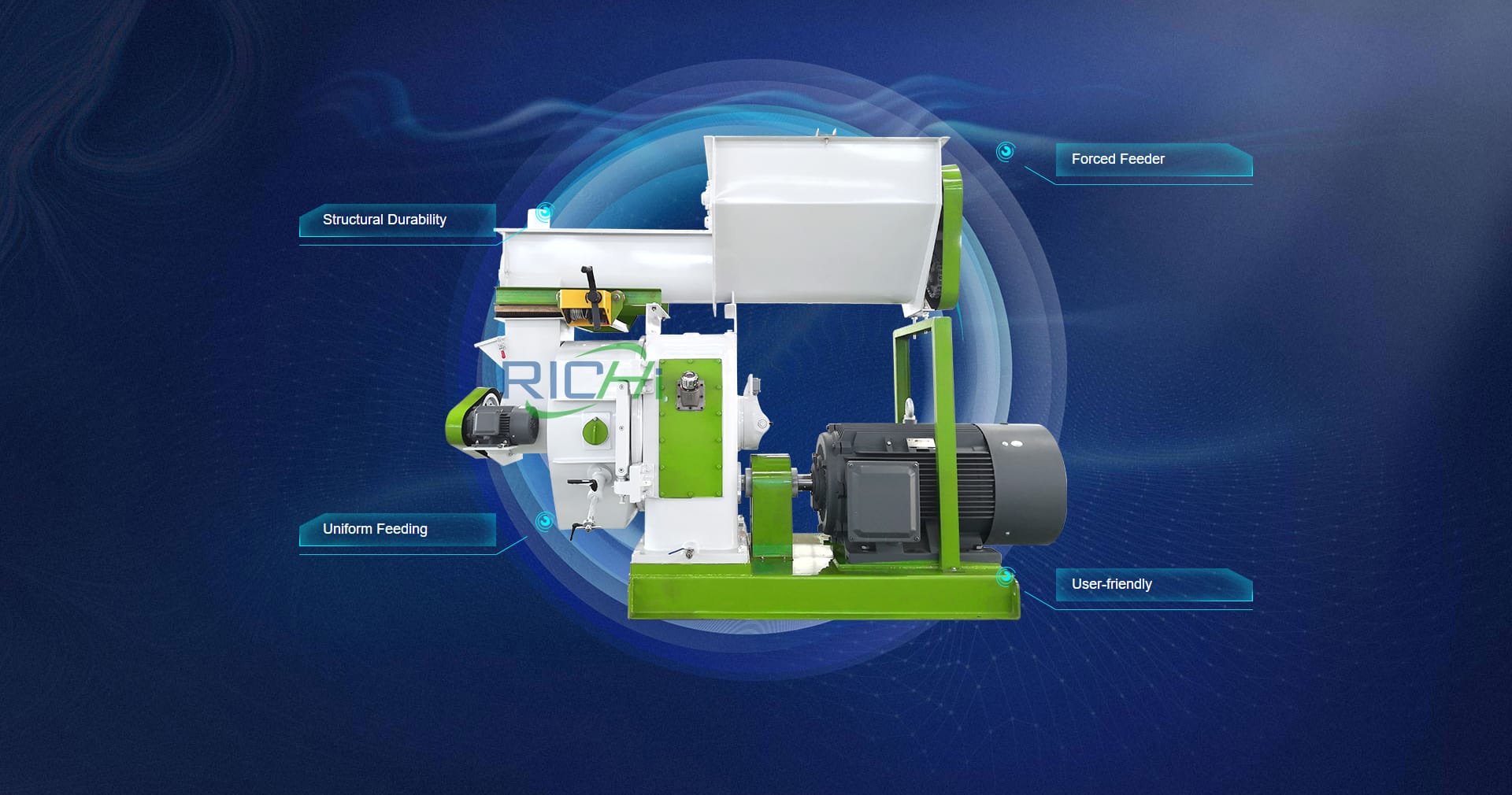

The core machine for pellet production

Estimated cost: €40,000 – €60,000 - Cooling System

- Counterflow cooler

Estimated cost: €15,000 – €25,000

- Counterflow cooler

- Screening System

To remove fine particles and ensure uniform pellet size

Estimated cost: €10,000 – €15,000 - Packaging System

- Bagging machine

- Weighing equipment

Estimated cost: €20,000 – €30,000

- Dust Collection System

Essential for maintaining air quality and safety

Estimated cost: €15,000 – €25,000 - Control System

For automated operation of the entire production line

Estimated cost: €30,000 – €50,000 - Auxiliary Equipment

- Silos for raw material and finished product storage

- Screw conveyors

- Elevators

Estimated cost: €30,000 – €50,000

Total Estimated Equipment Cost

The total estimated cost for the equipment of a 1-2 T/H sawdust wood pellet production line in Italy ranges from €245,000 to €390,000. This range accounts for variations in equipment quality, brand, and specific features chosen.

Additional Considerations

- Installation and Commissioning

Costs for installation, setup, and initial testing can add approximately 15-20% to the equipment cost.

Estimated additional cost: €36,750 – €78,000 - Building and Infrastructure

If a new facility needs to be constructed or an existing one modified, this can significantly impact the overall project cost.

Estimated cost: €100,000 – €200,000 (highly variable based on location and existing infrastructure) - Permits and Certifications

Obtaining necessary permits and certifications for operation in Italy.

Estimated cost: €10,000 – €20,000 - Training and Initial Operations

Staff training and costs associated with initial production runs.

Estimated cost: €15,000 – €25,000

Factors Affecting Equipment Selection and Costs

- Raw Material Characteristics

The moisture content and particle size of the sawdust can influence the choice of drying and grinding equipment. - Production Capacity

A 1-2 T/H line allows for some flexibility. Equipment at the higher end of the capacity range will generally be more expensive but may offer better scalability for future expansion. - Energy Efficiency

More energy-efficient equipment may have higher upfront costs but can lead to significant savings in operational expenses over time. - Automation Level

Higher levels of automation increase initial costs but can reduce labor requirements and improve consistency in production. - Quality Standards

Equipment capable of producing pellets that meet stringent quality standards (e.g., ENplus certification) may be more expensive. - Local Regulations

Italian and EU regulations regarding emissions and safety standards can impact equipment selection and costs.

Cost-Saving Strategies

- Integrating with Existing Operations

For furniture factories or sawmills, integrating the pellet production line with existing operations can reduce costs for raw material handling and storage. - Phased Implementation

Starting with core equipment and adding peripheral systems over time can spread out the initial investment. - Exploring Used Equipment

While caution is needed, purchasing some components as used equipment can significantly reduce initial costs. - Local Sourcing

Sourcing some equipment or components from Italian or European manufacturers can reduce shipping costs and simplify maintenance.

Operational Costs to Consider

While not part of the initial equipment costs, it’s important to factor in ongoing operational expenses:

- Energy Costs

Electricity for running the equipment and potentially natural gas for the drying system. - Labor

Skilled operators and maintenance personnel. - Maintenance and Spare Parts

Regular maintenance and replacement of wear parts, especially for the pellet mill. - Raw Material

While often a byproduct for integrated operations, any additional sawdust purchases should be considered.

Conclusion

Establishing a 1-2 T/H sawdust wood pellet production line in Italy requires a significant investment, with equipment costs ranging from €245,000 to €390,000, and total project costs potentially reaching €500,000 to €700,000 when including installation, building modifications, and other associated expenses.

The exact cost will depend on various factors including the specific equipment chosen, the level of automation, and whether the line is being integrated into an existing facility or built as a standalone operation. While the initial investment is substantial, the growing market for wood pellets in Italy and across Europe offers promising opportunities for return on investment.For furniture factories or wood processing facilities in Italy, adding a pellet production line can be an excellent way to monetize sawdust and wood waste while contributing to renewable energy production.

The key to success lies in careful planning, selecting the right equipment for the specific operational needs, and ensuring compliance with all relevant Italian and EU regulations.Potential investors should conduct thorough market research, possibly engage with equipment suppliers for detailed quotes, and consider consulting with industry experts to refine their plans and cost estimates. With the right approach, a 1-2 T/H sawdust wood pellet production line can be a valuable addition to Italy’s growing renewable energy sector.