In the ever-evolving landscape of renewable energy sources, the utilization of biomass has emerged as a promising solution to reduce our reliance on fossil fuels and mitigate the impact of climate change. Among the various biomass feedstocks, wood chips have gained significant attention due to their abundance and unique properties. Enter wood chip pellet machines, specialized equipment designed to transform wood chips into compact and energy-dense pellets, offering a viable and efficient fuel source for heat and power generation.

The Significance of Wood Chip Biomass

Wood chip biomass, derived from forestry residues, sawmill by-products, and other woody materials, has emerged as a valuable resource in the renewable energy sector. The significance of wood chip biomass as a fuel source extends beyond its renewable nature, offering numerous advantages:

- Abundant and Renewable: Wood chips can be sourced from sustainable forestry practices, ensuring a continuous supply of biomass feedstock while promoting responsible resource management.

- High Energy Density: Wood chip pellets have a higher energy density compared to other biomass sources, making them an efficient and cost-effective fuel for various applications.

- Low Emissions: When burned for energy, wood chip pellets typically have lower emissions compared to traditional fossil fuels, contributing to a cleaner and more sustainable energy solution.

- Versatility: Wood chip pellets can be utilized in a wide range of applications, including residential heating, industrial boilers, and co-firing in power plants, offering flexibility in energy production.

- Local Sourcing: Wood chip biomass can often be sourced locally, reducing transportation costs and supporting regional economies while promoting energy independence.

The Role of Wood Chip Pellet Machines

Wood chip pellet machines play a crucial role in transforming raw wood chip biomass into a convenient and efficient fuel source. These specialized machines offer numerous benefits:

- Increased Energy Density: By compressing and densifying wood chips into pellets, these machines significantly increase the energy density of the fuel, facilitating efficient transportation, storage, and combustion.

- Consistent Quality: Advanced wood chip pellet machines incorporate quality control measures to ensure consistent pellet size, density, and moisture content, promoting uniform combustion and energy output.

- Efficient Processing: These machines streamline the biomass processing workflow, integrating various stages such as drying, grinding, and pelleting, resulting in increased efficiency and productivity.

- Reduced Emissions: Wood chip pellets produced by these machines typically have lower emissions compared to traditional fossil fuels, contributing to a cleaner and more sustainable energy solution.

- Versatility: Wood chip pellet machines can be configured to process a variety of wood chip feedstocks, offering flexibility in raw material sourcing.

- Scalability: These machines are available in various capacities, allowing for scalable operations to meet the growing demand for wood chip pellets in residential, commercial, and industrial applications.

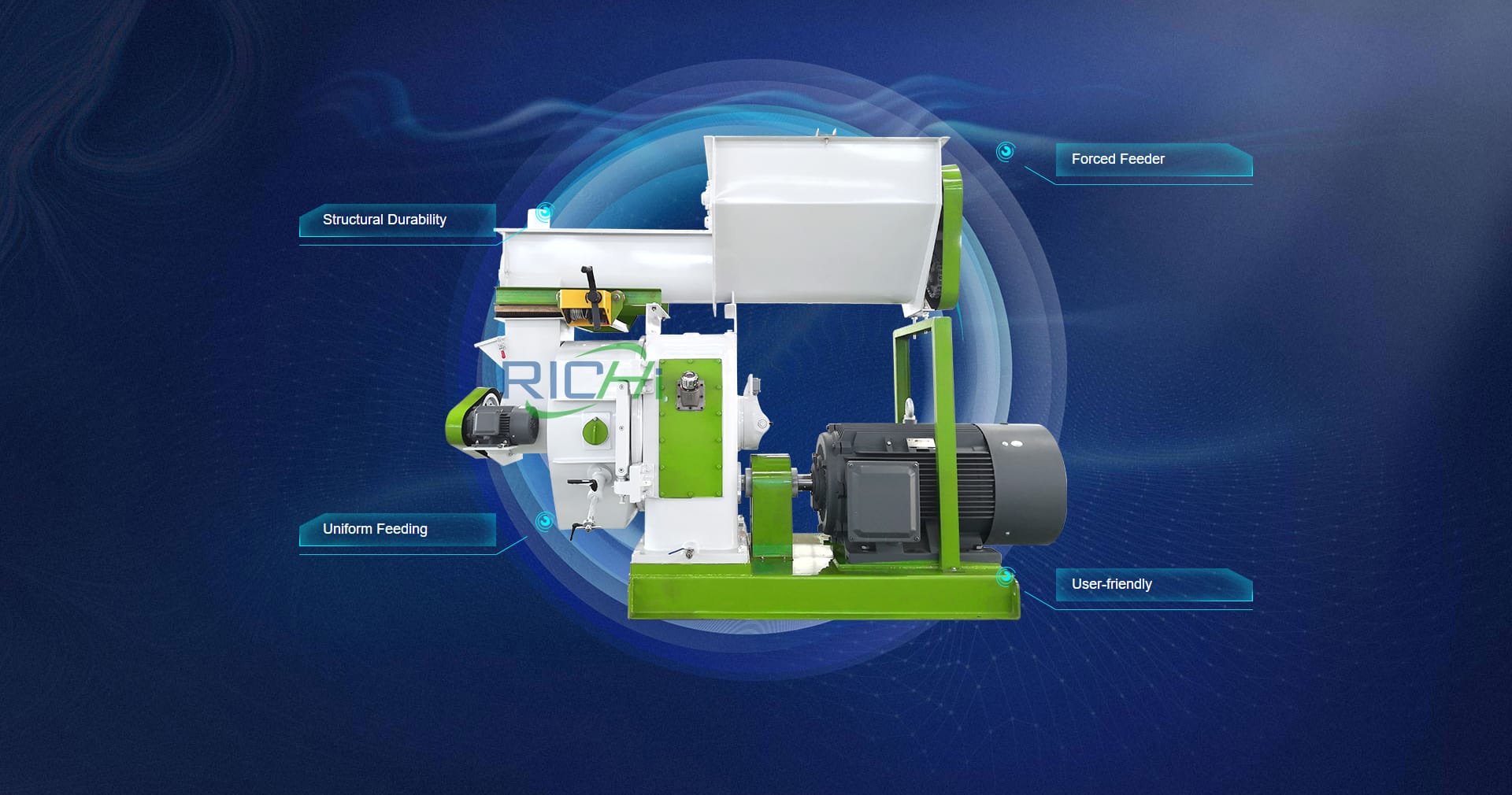

Key Components of Wood Chip Pellet Machines

A successful wood chip pellet machine operation requires the integration of various components to ensure efficient and sustainable production. The key components of a typical wood chip pellet machine include:

- Drying System: Efficient drying systems are essential for reducing the moisture content of wood chips to optimal levels, ensuring proper pellet formation and combustion characteristics.

- Grinding and Milling: Advanced grinding and milling equipment is necessary to achieve the desired particle size and texture of the wood chip material, facilitating efficient pelleting.

- Mixing and Conditioning: Mixing and conditioning systems ensure homogeneous distribution of the biomass material and optimal moisture levels, promoting consistent pellet quality.

- Pelleting Unit: The heart of the machine, the pelleting unit compresses and extrudes the wood chip material into dense, durable pellets through the application of heat and pressure.

- Cooling and Drying: After pelleting, efficient cooling and drying systems are crucial for stabilizing the pellets and preventing moisture buildup, ensuring long-term storage stability.

- Quality Control and Monitoring: Comprehensive quality control measures, including in-line monitoring systems and laboratory testing, are essential to ensure that the final wood chip pellets meet stringent quality and safety standards.

- Automation and Process Control: Advanced automation and process control systems are integrated into wood chip pellet machines to ensure consistent product quality, maximize efficiency, and minimize downtime.

- Auxiliary Systems: Wood chip pellet machines also require auxiliary systems such as material handling equipment, dust collection systems, and utilities to ensure efficient and safe operations.

Related post: https://www.richipelletmachine.com/biomass-pellet-project-cost/

Factors Influencing Wood Chip Pellet Machine Success

The success of a wood chip pellet machine operation is influenced by several critical factors, including:

- Wood Chip Supply and Quality: Securing a reliable and cost-effective supply of high-quality wood chips is crucial for consistent pellet production and profitability.

- Formulation Expertise: Employing skilled biomass specialists and process engineers is essential to optimize the pellet production process and ensure consistent pellet quality.

- Technology and Automation: Investing in advanced technologies and automation systems can enhance production efficiency, reduce labor costs, and improve product quality and consistency.

- Energy Efficiency and Sustainability: Incorporating energy-efficient technologies and sustainable practices, such as waste heat recovery and renewable energy sources, can reduce operational costs and minimize the environmental impact of the wood chip pellet machine operation.

- Regulatory Compliance: Ensuring compliance with relevant regulations and standards related to emissions, air quality, and environmental protection is essential for the long-term viability of the wood chip pellet machine operation.

- Skilled Workforce and Training: Employing a skilled and well-trained workforce is crucial for the efficient operation and maintenance of the wood chip pellet machine facility, ensuring optimal performance and minimizing human errors.

- Continuous Improvement: Implementing a culture of continuous improvement, including regular equipment upgrades, process refinements, and the adoption of new technologies, can drive long-term efficiency gains and maintain competitiveness in the biomass energy market.

Opportunities and Future Outlook

As the global demand for renewable and sustainable energy solutions continues to rise, the wood chip pellet machine industry is poised for significant growth, creating numerous opportunities. The future outlook for this sector is promising, driven by factors such as:

- Increasing Demand for Renewable Energy: The growing emphasis on reducing greenhouse gas emissions and mitigating climate change is expected to drive the demand for renewable energy sources like wood chip pellets, supporting the expansion of wood chip pellet machine operations.

- Technological Advancements: Ongoing research and development in areas such as biomass processing, pellet quality optimization, and combustion technologies will contribute to the development of more efficient and innovative wood chip pellet machines and energy systems.

- Sustainable Forestry Practices: The adoption of sustainable forestry practices, including responsible wood harvesting and reforestation efforts, will ensure a continuous supply of wood chip biomass feedstock for pellet production.

- Decentralized Energy Solutions: The growing trend towards decentralized and localized energy production will create opportunities for small-scale and community-based wood chip pellet machine operations, promoting energy independence and resilience.

- International Collaboration and Investment: Increased international collaboration and investment in renewable energy solutions will drive the development of new wood chip pellet machine facilities, fostering economic growth and technological advancements.

In conclusion, wood chip pellet machines play a crucial role in unlocking the potential of wood chip biomass as a sustainable and efficient energy source. By investing in these specialized machines and embracing innovative biomass energy solutions, stakeholders can contribute to meeting the rising global demand for renewable energy while promoting sustainable practices and economic development. As the world continues to recognize the importance of transitioning towards a low-carbon future, wood chip pellet machines will remain at the forefront of this vital industry, fueling its growth and driving innovation for a more prosperous and responsible future.