Richi Machinery is a professional manufacturer of organic fertilizer pellet making machine. The products are made of fresh chicken and pig manure and do not contain any chemical ingredients. However, chickens and pigs have poor digestion ability and can only consume 25% of the nutrients.

The other 75% of the nutrients are excreted with the feces, so that the dry product contains nitrogen, phosphorus, potassium, organic matter, amino acids, protein and other ingredients. Chicken manure dryer not only creates economic benefits for enterprises, but also makes great contributions to human environmental protection projects.

1. What’s organic fertilizer?

What’s organic fertilizer made by organic fertilizer pellet making machine and organic fertilizer production line?

Organic fertilizers are rich in organic matter, which can provide nutrients for crop growth, and can also fertilize and improve soil. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing.

It provides the nutrients needed for crop growth, and the nutrients are comprehensive. It contains 16 kinds of nutrients necessary for the growth of crops, and also contains other elements that are beneficial to the growth of crops, which can comprehensively promote the growth of crops, and the nutrients are released evenly and for a long time.

The nutrients contained in organic fertilizer are more than It exists in organic form and can be released slowly to supply nutrients to crops for a long time. The application of organic fertilizer can improve the soil structure and enhance soil fertility.

Organic fertilizer made by organic fertilizer pellet making machine can increase the soil water holding capacity, which can generally be increased by about 10 times. It also has good drainage, so it can alleviate the difference between soil dryness and wetness, and the root environment of crops will not be too much. too large or too small.

2. Advantages of organic fertilizer pellet making machine:

- Compared with natural agglomeration granulation devices (such as rotary disc organic fertilizer pellet making granulator, drum organic fertilizer pellet making machine), it has a concentrated particle size distribution and is easy to control.

- High efficiency and easier to meet the requirements of large-scale production.

- The spherical particles have no acute angle after granulation, so the pulverization rate is extremely low.

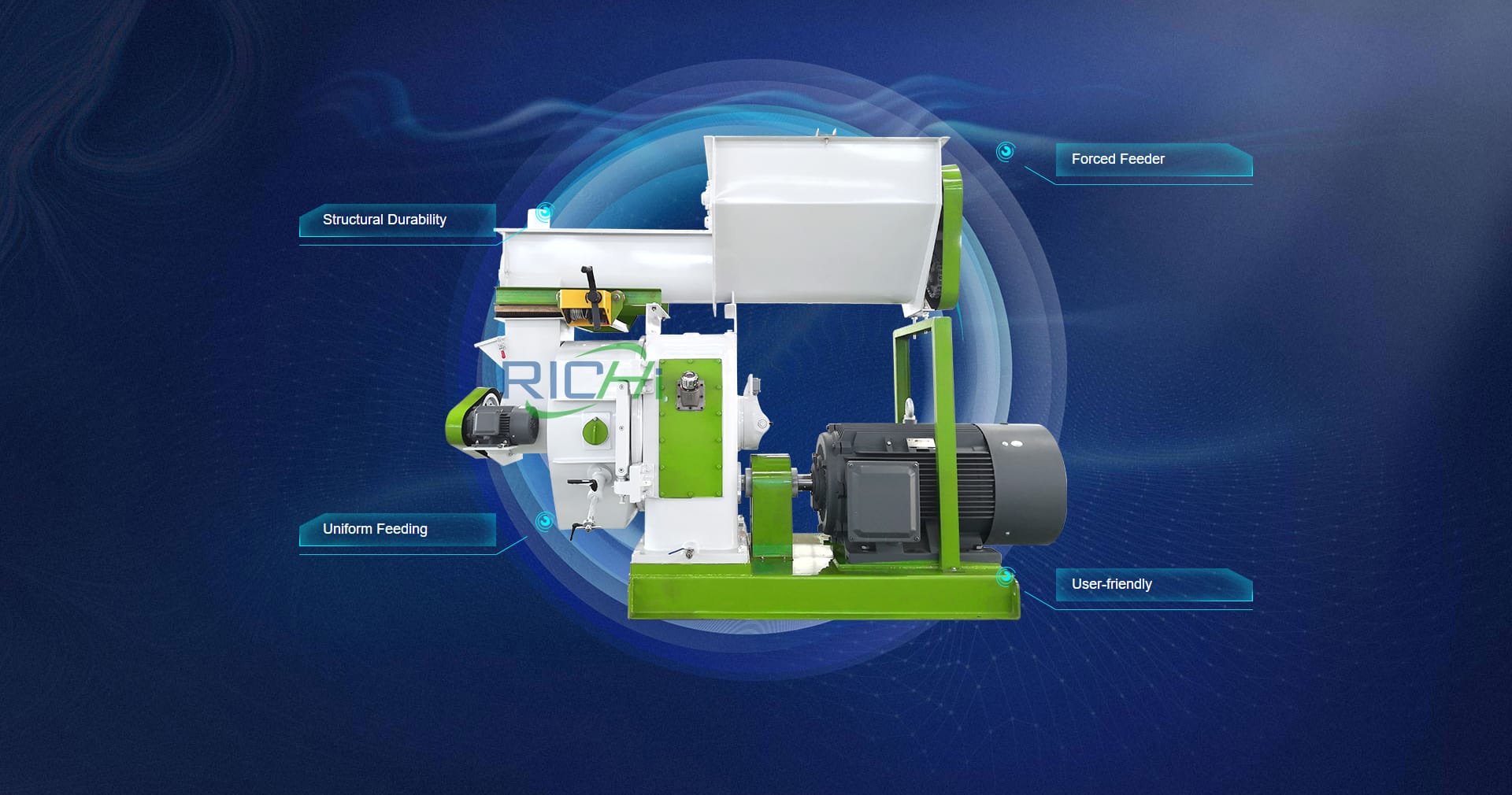

3. Features of RICHI organic fertilizer pellet making machine:

The granules produced by RICHI organic fertilizer pellet making machine are spherical. The organic content can be as high as 100,000 to achieve pure organic granulation. Taking advantage of the fact that organic particles can inlaid and grow with each other under a certain force, no binder is required during granulation.

The granules are firm and can be screened after granulation, reducing drying energy consumption. The organic matter after fermentation does not need to be dried, and the moisture content of the raw material can be 20-40%.

4. Application scope of organic fertilizer pellet making machine:

The organic fertilizer pellet making machine is favored by the majority of users, and the internal rotating organic fertilizer pellet mill is widely used in the granulation of organic fertilizers. Due to the high granulation rate, stable operation, durable equipment and long service life, it is selected as the ideal product by the majority of users.

The stirring tooth organic fertilizer pellet making machine is suitable for organic fertilizer raw materials such as livestock and poultry manure, composting fertilizer, green manure, sea fertilizer, cake fertilizer, peat and soil fertilizer. The qualified granulation rate of this machine is as high as 90 or more.

Adapt to a variety of different formulas, the compressive strength of organic fertilizer is higher than that of discs and drums, the percentage of large balls is lower than 15%, and the uniformity of particle size can be adjusted according to user requirements through the stepless speed regulation function of the machine.

This organic fertilizer pellet making machine is more suitable for direct granulation of organic fertilizer after fermentation, which saves the drying process and greatly reduces the manufacturing cost.

5. Working principle of organic fertilizer making machine:

Using the mechanical stirring force of high-speed rotation and the resulting aerodynamic force, the fine powder material can be continuously mixed, granulated, spheroidized and densified in the machine, so as to achieve the purpose of granulation. The particle shape from the organic fertilizer pellet making machine is spherical, the sphericity is greater than or equal to 0.7, the particle size is generally between 0.3 and 3 mm, and the granulation rate is greater than or equal to 80%. The higher, the smaller the particles, and vice versa.

6. Organic fertilizer granulator production line

It is produced by non-drying and normal temperature process, one-time molding, and the output is 1-1.5t/h and 1.5-3th/h. The equipment has low investment, quick effect and good economic benefits.

The complete set of organic fertilizer pellet making machine has a compact process layout, scientific and reasonable, and advanced technology. Energy saving and consumption reduction, no discharge of three wastes, stable operation, reliable operation and convenient maintenance.

The raw material has wide adaptability and is suitable for granulation of various raw materials such as compound fertilizer, medicine, chemical industry, feed, etc. The product has a high granulation rate. It can produce various concentrations and various types of compound fertilizers (including organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, etc.).

In particular, the granulation of rare and ammonium bicarbonate series compound fertilizers fills the domestic gap and ranks at the domestic level.

The organic fertilizer pellet making machine production line is designed and manufactured according to the requirements of compound fertilizer plants and fertilizer distributors, with an output of 10,000 to 100,000 tons.

It adopts the process of direct feeding from the hoisting tank and direct unloading of the mixer, which almost achieves the goal of “zero” blanking. The main organic fertilizer pellet making machine adopts forward and reverse operation, and the material is stirred and output through a special internal screw mechanism and a unique three-dimensional structure.

Features of organic fertilizer pellet making machine plant:

①Fully automatic. The organic fertilizer pellet making machine production line is composed of three parts: automatic batching system, mixing system and quantitative packaging machine. It is controlled by computer and fully automatic production. Greatly reduces the number of staff and reduces labor intensity.

②High precision. The batching system is computer-controlled, electronic weighing, and strictly controls the proportioning. For various ingredients, the error after electronic quantitative packaging is less than one thousandth.

③The output is large. The design output of the organic fertilizer pellet making machine production line is 8T to 30T per hour, and there are three specifications to choose from. This fully solves the contradiction of organic fertilizers due to the strong seasonal concentration of materials.

④ New technology.

- The mixing system adopts a drum type non-destructive mixer and a barrel type feeder, which not only does not damage the original particle shape of the material, but also prevents the segregation of the finished product after mixing; batch batch mixing, high mixing uniformity. The blade of the mixer is uniquely designed, the mixing is uniform, and the material is fed and discharged quickly. Effectively improve product quality and market competitiveness.

- In view of the humid climate, relatively small production workshop and high labor cost, XYPF-B series (ground feeding method) production line equipment, the batching system is installed under the barrel, the organic fertilizer pellet making machine production line is compact, and the floor area is small, and it is directly on the ground. material, the labor intensity is relatively small. The unique barrel-type lifting device minimizes the contact between the material and the air, and avoids the moisture absorption of the material during the production process.

- XYPF-Ⅱseries anti-corrosion model adopts different special anti-corrosion measures, which greatly prolongs the service life of the equipment, and is especially suitable for use in rainy and humid areas.

- The organic fertilizer pellet making machine production line does not have any dead corners, and it is convenient and simple to clean up after shutdown.

⑤Easy to manage. The main control room of the organic fertilizer pellet making machine production line can monitor the running status of each component equipment. The high-speed 485 or 232 communication interface is convenient for connecting with printers and computers. It can store 20 kinds of formulas, and truly realize the modernization of production management.

⑥Strong adaptability. The organic fertilizer pellet making machine plant is suitable for all kinds of harsh field environments, including alpine areas and humid areas.